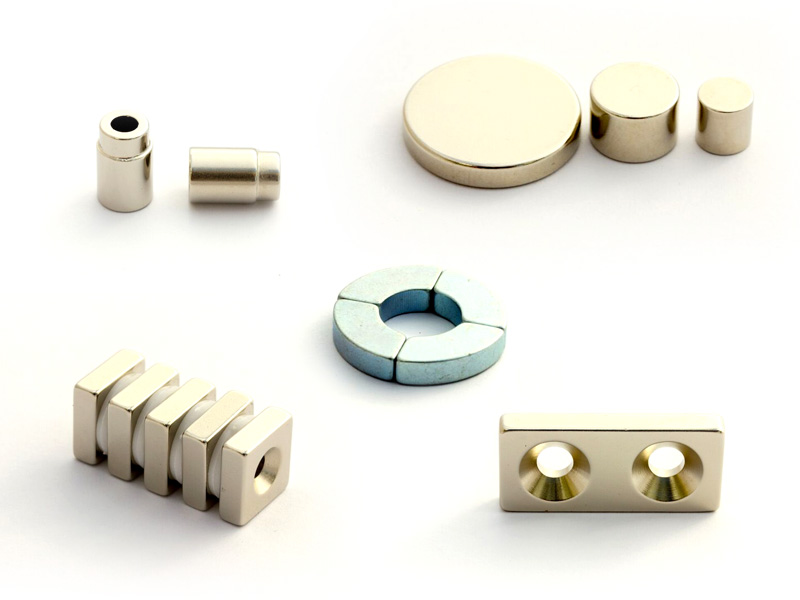

Home » Permanent Magnets » Neodymium Rare Earth Magnets

Rare earth Neodymium magnets (NdFeB) have been available for industrial use since 1984. Neo magnets have extremely high magnetic energy and therefore are used in applications that require high-powered magnets and applications where size and weight reduction are of interest or need to be considered. These qualities have made NdFeB magnets preferable over the commonly used larger and less powerful Ferrite magnets.

Neo magnets are known for their high-temperature resistance, making them durable and functional in temperatures exceeding 200°C. This quality makes them ideal for heavy industry applications. Sintered Neodymium, however, is sensitive to oxidization and can develop corrosion, so magnets are usually coated with Zinc, Nickel (and more different coatings) for their protection.

NdFeB magnets can be used for a wide variety of applications, for example: